By Katherine Wroth

•

November 28, 2025

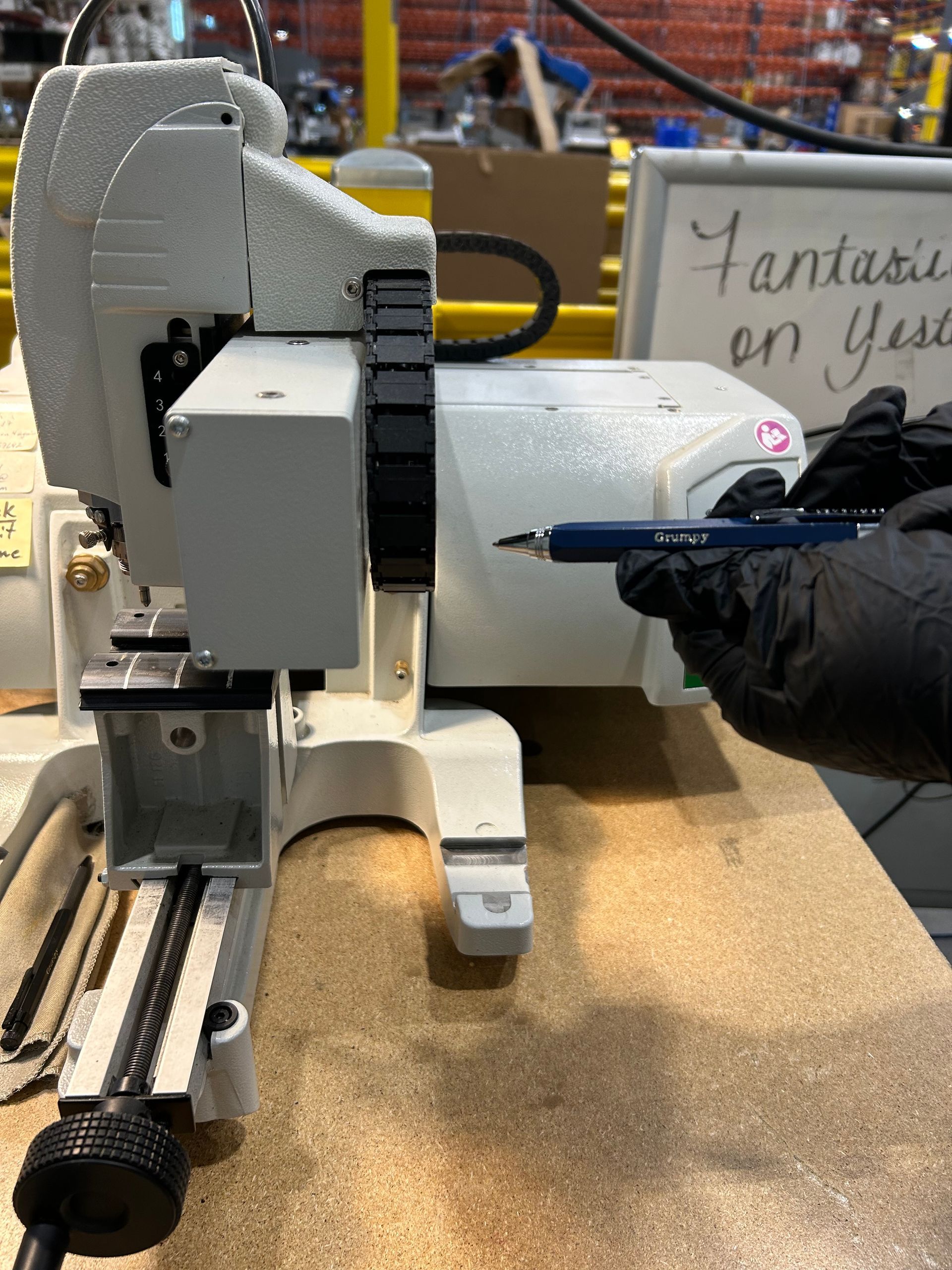

As a marketer, I can’t help but think about how much “fluff” is in advertising and how people are bombarded daily with thousands of generic messages. And as I begin my holiday shopping, it honestly hurts my soul knowing that dad is getting another set of generic socks, sister is getting another plain ceramic coffee mug, and mom is getting another non-stick pan that will end up with the hundreds she already has. Then I started noticing people line up for HOURS to get their bags monogrammed, their journals engraved, and their gifts wrapped with custom notes — and it hit me. Personalization is all about a feeling. The feeling that you thought deeply about someone when choosing a gift, and that it wasn’t just another HomeGoods candle regift (we’ve all been there — no judgment, but I am squinting). And yes, these are the things that keep me up at night. But on a larger scale, I’m always thinking about what brands could be doing better. And the data is in: personalization is one of the most effective ways to stand out. According to Salesforce, 78% of consumers are more likely to repurchase from brands that personalize their offerings , and Adobe reports that 52% of consumers now expect personalized offers from retail brands . What used to be a “nice touch” is now the expectation. Below are the personalization trends we see leading the charge this holiday season — many of which you’ll spot in our recent personalization workflow video. 1. Monogramming is having a moment Embroidery remains one of the most requested personalization services. It creates an emotional connection that gift shoppers love, and when it’s built directly into fulfillment operations, it avoids the bottlenecks brands often face. 2. UV printing is becoming a go-to for fast customization UV printing delivers a premium look quickly and works across a wide range of materials. It provides brands with the flexibility to offer personalization without compromising shipping promises. 3. Laser engraving continues to stand out for gifting Engraving adds depth, permanence, and a premium feel that elevates even simple products. With 86% of shoppers stating that personalization influences their purchasing decisions , engraving has become a strategic differentiator for gifting moments. 4. Debossing is rising in popularity for premium and corporate gifting The subtle, elevated finish resonates with shoppers seeking something that feels intentional and gives professional vibes. It also photographs beautifully, which matters when unboxing content drives discovery. 5. Handwritten notes still matter There’s nothing more human than a handwritten message. A simple note can turn a routine order into a moment worth sharing, and shoppers notice the effort. 6. Gift wrapping expectations are higher than ever Gift wrapping used to be a “nice-to-have." Shoppers want gifts to arrive ready to give, and they expect the wrap to match the quality of the item. When a 3PL integrates wrapping into its workflow, brands get consistency without sacrificing speed. 7. Kitting and curated sets are on the rise Gift sets and bundles remain one of the strongest trends of the season. Customers love the convenience and the elevated presentation, but behind the scenes, kitting requires organization and accuracy — especially during peak. That’s where strong fulfillment workflows matter. 8. Custom packaging shapes the unboxing experience Personalized tissue, belly bands, stickers, sleeves, and inserts transform a simple shipment into a brand moment. Deloitte found that 54% of consumers expect a personalized unboxing experience , and 70% say that custom packaging enhances their perception of a brand . Packaging is all about storytelling. Why personalization matters more this season Across retail, personalization drives: Higher repeat purchases Increased AOV Stronger first impressions Better loyalty More organic social content With 40% of consumers spending more than planned when they receive personalized experiences , the value is undeniable. The brands that stand out are the ones that can deliver personalization consistently, accurately, and quickly — especially when volume spikes. How ���Ҵ�ý brings personalized fulfillment to life Within ���Ҵ�ý facilities, personalization is an integral part of the operational workflow for many of our partners. Our teams support brands with: Monogramming and embroidery UV printing Laser engraving Debossing Gift wrapping Handwritten notes Custom packaging setups Kitting and bundling Real-time visibility and reporting Brands get the elevated customer experience they want without compromising speed or accuracy. Big plans for custom services next year? If your brand wants to introduce new custom services or scale the ones you already have, an experienced 3PL partner is non-negotiable. Contact us for a free personalization supply chain consultation today.